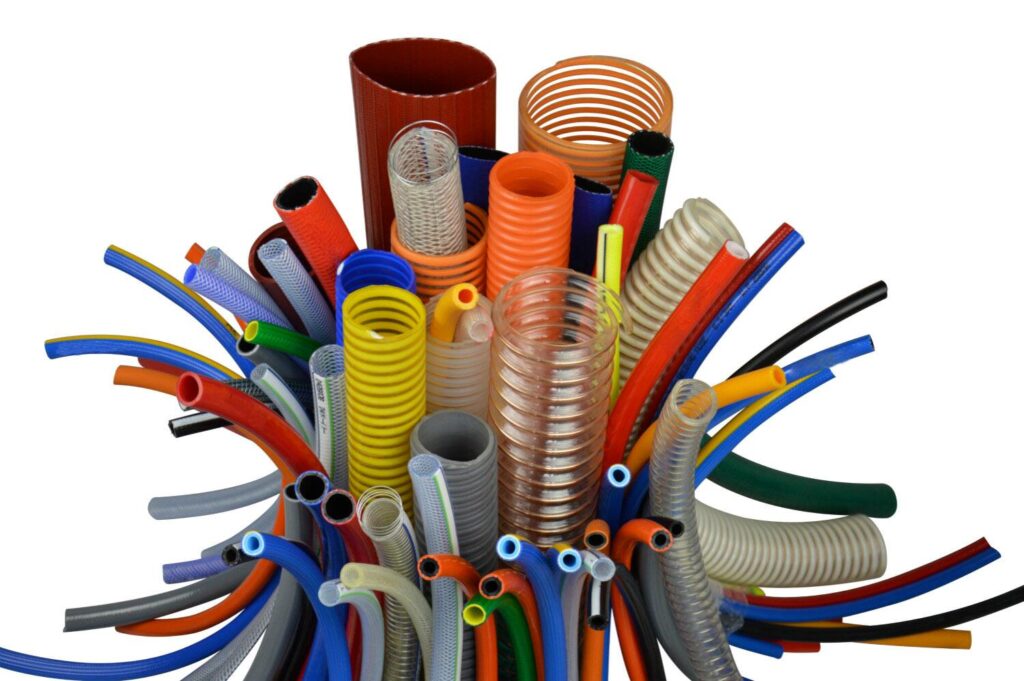

The PVC HOSE Manufacturer industry has experienced significant advancements over the years, driven by technological innovations, changing market demands, and a growing emphasis on sustainability. As we look to the future, several trends and innovations are poised to reshape the PVC hose manufacturing landscape. This article explores the emerging technologies and developments that are expected to influence the industry in the coming years.

1. Advanced Manufacturing Techniques

The manufacturing process for PVC hoses is evolving, with new technologies enhancing efficiency, precision, and product quality.

- 3D Printing: Additive manufacturing, commonly known as 3D printing, is making waves in the PVC hose industry. This technology allows for rapid prototyping and production of customized hose designs that meet specific customer needs. As 3D printing technology advances, it will enable manufacturers to create intricate hose structures and configurations that were previously difficult or impossible to achieve.

- Automated Production Lines: Automation is transforming traditional manufacturing processes, improving speed and consistency. Automated production lines equipped with robotic systems can reduce human error and increase production capacity. This not only leads to higher efficiency but also enables manufacturers to meet the growing demand for PVC hoses in various industries.

2. Smart Hose Technology

The integration of smart technology into PVC hoses is an exciting development that offers new possibilities for monitoring and performance optimization.

- IoT Integration: Internet of Things (IoT) technology is being embedded in PVC hoses, allowing for real-time monitoring of critical parameters such as pressure, temperature, and flow rates. IoT-enabled hoses can send data to centralized systems, providing operators with valuable insights for managing processes and preventing potential failures.

- Predictive Analytics: With the data collected from smart hoses, manufacturers and users can leverage predictive analytics to anticipate maintenance needs and avoid costly downtime. By analyzing trends in hose performance, businesses can optimize their maintenance schedules and improve overall operational efficiency.

3. Sustainability Initiatives

Sustainability is becoming a priority for manufacturers and consumers alike, driving innovations in the PVC hose industry.

- Recyclable Materials: Manufacturers are exploring the use of recyclable PVC materials in hose production. This not only helps reduce waste but also aligns with the growing demand for eco-friendly products. By offering recyclable hoses, manufacturers can appeal to environmentally conscious consumers and businesses.

- Biodegradable Options: Research into biodegradable PVC formulations is gaining traction. These innovative materials break down more naturally over time, reducing environmental impact. As the technology matures, we may see a shift toward more widespread adoption of biodegradable PVC hoses in various applications.

4. Enhanced Customization and Specialization

The demand for customized solutions is on the rise as industries become more specialized.

- Tailored Solutions: Manufacturers are increasingly offering tailored hose solutions designed to meet specific application requirements. This includes hoses designed for unique fluids, extreme temperatures, or specific pressure ratings. The ability to customize hoses enhances their performance and reliability in various environments.

- Specialized Applications: As industries continue to evolve, there is a growing need for specialized hoses that cater to unique applications. Manufacturers are investing in research and development to create hoses designed for niche markets, such as pharmaceutical processing, food and beverage transport, and chemical handling.

5. Focus on Safety and Compliance

With the increasing complexity of regulations and safety standards, manufacturers are prioritizing compliance and safety features in their products.

- Enhanced Safety Features: Innovations in hose design are focused on improving safety, such as developing burst-resistant hoses or those with anti-static properties. These features help minimize risks associated with fluid transfer, particularly in hazardous environments.

- Regulatory Compliance: Manufacturers are investing in understanding and complying with evolving regulations across various industries. This includes ensuring that hoses meet safety standards for specific applications, such as food-grade certifications for hoses used in food and beverage processing.

6. Collaboration and Partnerships

Collaboration within the industry is becoming more prevalent as manufacturers seek to leverage complementary strengths.

- Industry Partnerships: Manufacturers are forming partnerships with technology companies, research institutions, and industry organizations to drive innovation and share knowledge. These collaborations can lead to new product developments and advancements in manufacturing processes.

- Customer Engagement: Manufacturers are increasingly engaging with customers to understand their needs and preferences. This customer-centric approach enables manufacturers to develop products that address real-world challenges, ultimately leading to greater satisfaction and loyalty.

7. Global Market Expansion

As emerging markets continue to grow, the demand for PVC hoses is expected to increase, presenting opportunities for manufacturers.

- Market Penetration: Manufacturers are exploring expansion into emerging markets where industrial growth is rapidly increasing. By tailoring products to meet local needs, they can capture a larger share of these growing markets.

- Global Supply Chains: The globalization of supply chains is allowing manufacturers to source materials and components from various regions, enhancing production capabilities and cost-effectiveness. This trend also enables manufacturers to respond more flexibly to changing market demands.

Conclusion: Embracing the Future

The PVC hose manufacturing industry is on the brink of significant transformation, driven by technological advancements, sustainability initiatives, and a focus on customization. As manufacturers embrace these trends and innovations, they will enhance their ability to meet the evolving demands of various industries.

By prioritizing smart technology integration, sustainable practices, and safety features, the PVC HOSE Manufacturer industry can position itself for growth and success in the years to come. As we move forward, it will be essential for manufacturers to remain adaptable and responsive to the changing landscape, ensuring that they continue to deliver high-quality, reliable, and innovative hose solutions for a diverse range of applications.